Polyurethane foam vs Mineral wool

Spray foam insulation or mineral wool?

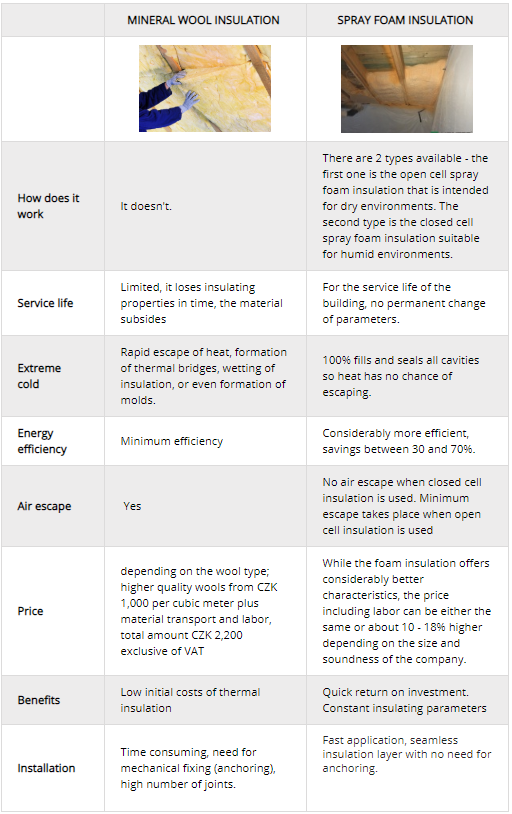

Mineral wool insulation is less efficient than insulating foams, particularly at extremely low temperatures. The main reason consists in air tightness. Mineral wool regardless of the installation quality, it does not form air barrier and enables free air passage through its joints. The interior air and outside air, each with different temperature, thus meet in the vicinity of the insulation inside the building structure. Vapor starts to condense, which results in moisture formation within the insulation that you can hardly remove. Wet mineral wool loses its insulating properties.

When compared to mineral wool insulation, the undisputable benefit of the spray foam insulation consists in its joint-free technology which forms consistent thermal insulation layer.

Comparing thickness of the thermal insulation obtained using expanded polystyrene, mineral wool and polyurethane rigid foam.

The most common thermal insulating materials on the market in Europe are MW and EPS. However, the PUR and PIR insulation is gaining attention due to its superior

thermal performance and decreasing costs of production. These are important advantages in the increasingly stringent thermal requirements of buildings because the traditional insulation materials must increase its already considerable thickness to about 20 cm. In addition, research to improve the properties of the PU is ongoing and it makes this material

more attractive on the construction market.